VD3-81 Eddycon portable eddy-current flaw detector

|

|

||

PURPOSE

VD3-81 eddy current flaw detector Eddycon is referred to the testing and evaluation means.It is intended for manual testing by eddy current technique for the presence of surface and subsurface defects, such as discontinuity of the material (cracks, overlaps, holes, fine cracks, etc.)

IT IS APPLIED IN THE FOLLOWING BRANCHES OF INDUSTRY:

AIRCRAFT testing of aeronautical engineering parts (wheel disks, covering, turbine blades, multilayered constructions, holes of various kinds etc.).

OIL-AND-GAS testing of pipelines, turbine blades of gas-distributing station (GDS), pressure vessels, etc.

CHEMICAL testing of pipelines, industrial vessels etc.

POWER testing of steam generator pipes by inner bobbin eddy current probes ,( I/D ECP), collectors etc.

ENGINEERING testing of rods, wire, metalwares, forming rolls, sheet metals, metal parts of bearing structures etc.

FLAW DETECTOR AVANTAGES

- Possibility of tuning out from the influence of operating liftoff of testing object electromagnetic properties inhomogeneity;

- Storage of a great number of setups and testing results in the flaw detector memory;

- Special-purpose software;

- Mode of two-way connection with PC via USB port;

- Possibility of conditional defect depth and length evaluation;

- Sound and color ALARM system.

- Operation simplicity due to the intuitive interface;

- easily removable storage battery;

- Small mass and dimensions parameters;

- device complies with European Standard 61326:2005(First edition).

Flaw detector distinctive features:

- Color high-contrast TFT display;

- ALARM system: 4 three-color LEDs, sound alarm; various scanning units manipulation;

- possibility of operation in two-frequency mode;

- simplified procedure of instrument calibration on calibration blocks;

- possibility of encoder and eddy current rotary scanner connection;

- possibility of rapid measurement of the ratio signal/noise;

- USB slave;

- possibility of low-temperature instrument version (minus 30 °С).

TECHNICAL SPESIFICATIONS AND SERIVCE FUNCTIONS OF THE INSTRUMENT

- The possibility of defects detection – from 0,1 mm and opening – from 0,002mm;

- operating frequency setup range – from 50 Hz to 12 МHz;

- generator output voltage (double amplitude) – from 0,5 V to 16 V;

- adjusted gain range - 30 dB;

- adjusted preamplifier range- 40 dB;

- signal phase change (range of signal rotation from 0 to 360 with a step of 0,1, 1, 10);

- samples frequency–up to 8 kHz;

- digital signal filtering (there are 5 filter types: Lowpass, Highpass, Bandpass, Differential, Averaging);

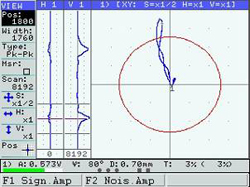

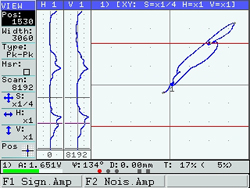

- eddy current signal display: a) complex plane (XY) – allows to detect defects among interferences by analyzing the signal waveform; b) generation of two channel maturing, can be used for suppression of interfering factors and reduction of their influence on testing results(for mixing an operator can choose one of 5 algorithms: addition, subtraction, addition with horizontal inversion, addition with vertical inversion and multiplication).

а)

б)

- two modes of instrument operation: day mode - is used when operating in dimly lit places with insufficient visibility; night mode - is used when operating in places with bright lighting, to increase the display contrast;

- time of flaw detector operation mode setup – up to 1 minute;

- autozap function(adjustable time of screen clearing in 0.1 s and 0.5 s, 1 s, 2 s, 3, 4);

- built-in clock and calendar;

- screen backlight and screen brightness control;

- congestion control of input channel;

- storage battery discharge level indication;

- possibility of connection and operation of ECP of the following types:

- differential ECP;

- differential ECP connected according to the bridge scheme;

- differential transformer ECP with grounded centerpoint;

- differential ECP of transformer type;

- absolute(parametric) ECP;

- absolute ECP of transformer type;

- possibility of eddy current rotary scanner connection for the testing of openings and special-purpose scanners;

- user-friendly multi-language interface;

- time of continuous flaw detector operation with the fully charged storage battery – at least 4,5 hours;

- total average life at least 10 years;

- flaw detector is powered from the built-in storage battery with rated voltage 12 V and rated capacity of 2700 mA * h;

- weight of flaw detector with a storage battery - no more than 0.8 kg;

- overall dimensions of flaw detector - no more than 210 mm x110 mm x 85 mm.

EXAMPLES OF FLAW DETECTOR APPLICATION

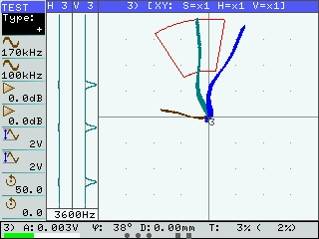

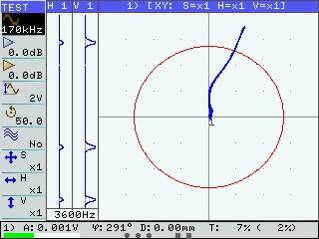

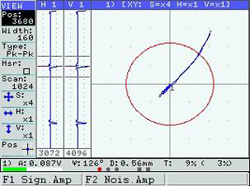

| Testing of bolt holes with the help of eddy current rotary scanner. | |

Signal projection (view) from a natural defect such as a crack with depth of 0.56 mm in the aircraft wheel bolt-hole. |

Circular scan allows an operator to place the defect in the hole. |

| Casting testing | |

Fatigue crack of 0,7 mm deep detected during testing of 18- 100 model bolster. |

Application of special-purpose PN-12- MDP- 01 and PN-09-MDP-01 probes in protective cases together with ALARM units and digital signal processing will allow to eliminate the influence of interfering factors such as roughness, edge effect, ECP separation from the testing object surface etc. Signals of stress-corrosion defect are obtained by VD3-81 flaw detector eddycon from the main gas pipeline section through the layer of insulation covering thickness of 6 mm.Application of VD3-81 flaw detector Eddycon for conduction of main or confirmatory body testing will enable to evaluate the pipe damage level and its further operability. |

| Testing of various purpose pipelines | |

Signals of stress-corrosion defect are obtained by VD3-81 flaw detector Eddycon from the main gas pipeline section through the layer of insulation covering thickness of 6 mm. |

Application of VD3-81 flaw detector Eddycon for conduction of main or confirmatory body testing will enable to evaluate the pipe damage level and its further operability. |

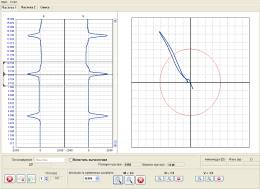

Software

Application of VD3-81 flaw detector Eddycon for conduction of main or confirmatory body testing will enable to evaluate the pipe damage level and its further operability.

Main advantages of program application are:

- An intuitive interface;

- Convenient view of testing results by each frequency channel (frequency № 1, frequency№ 2 mix.);

- Possibility of creation and storing of electronic records.

- Data output on the detected defect, namely:

- Coordinate position of the defect in the defectogramm;

- Amplitude and phase of the signal;

- Flaw depth.

Formed electronic report contains all basic data of conducted testing, namely:

- Information about the organization, NDT division and an operator who conducted the testing.

- denomination of the testing object;

- all flaw detector setups at the inspection moment;

- signal parameters from the defect (amplitude, phase,flaw depth);

- flaw signal in the complex plane and on the string diagramms;

- the date of testing

By agreement with the Customer there is a possibility to create other forms of reports.

| MAIN TECHNICAL SPECIFICATIONS | ||

| Frequency range | kHz | from 0,5 to 6000 |

| Gain | dB | 70 |

| Probe supply voltage | В | 0,5, 1, 2, 4, 8 |

| Sampling frequency | Hz | 8000 |

| Filter | Hz | Lowpass from 1 tо 5000; Highpass from 1 tо 5000; Bandpass filter; Differential; Averaging |

| Connected ECP | differential and absolute ECP; | |

| Digital zoom | from 1/16 to 16, with a step of 6 | |

| Phase rotation | °, degr. | from 0 to 360 |

| ECP connector | 2 - pin LEMO, 4 - pin LEMO | |

| Signal trace time | sec. | 0,1; 0,5; 1; 2; 3; 4 |

| Display | Color LCD | |

| Screen resolution | pixel | 320 x 240 |

| Screen size | Inch mm |

2,756 x 1,969 70 x 50 |

| Signal display modes | Complex plane – X(y); Time scan – X(t), Y(t); Vector – A(t); Circular scan – X(y)+A; |

|

| Defect alarm (alarm) | Frame: Circle: Sector: Cut-off: |

|

| Memory for setups and testing results storage | 1 Gb of memory. 1 defectogram occupies – 6 Мb; 1 setup occupies – 0,00355 Мb |

|

| Multi-frequency operation | 2 – frequency multiplexing; Independent control of both frequencies; Signals mix for unwanted effects rejection |

|

| Battery | Storage battery Hi-MH 12В/2700 mА×h | |

| Operation time from the battery | hour. | no less than 4,5 |

| Operating temperatures | °С | from -10 to +40 |

| Protection from environmental impact | IP 65 according to GOST 14254 | |

| Overall dimensions | mm | 210 x 110 x 85 |

| Weight with storage battery | kg | no more than 0,8 |

RANGE OF PRODUCTION PROBES

| № | Designation surface |

Sizes of working mm |

Operation frequency, dimensions, kHz |

Overall Dimensions mm |

Defected flaws |

|

| 1 | PN – 05-MDF01 | Æ4 | 500-2000 | Æ13×35 | Surface defects in different conduction materials (e.g. aluminum alloys, ferromagnetic and austenitic steel). |

|

| 2 | PN – 06-MDF01 | Æ5 | 500-1500 | Æ13×35 | ||

| 3 | PN – 07-MDF01 | Æ6 | 300-600 | Æ13×35 | ||

| 4 | PN –08-MDF01 | Æ7 | 200-400 | Æ13×35 | Surface and subsurface cracks, voids, corrosion damages in aluminum alloys , ferromagnetic and austenitic etc. | |

| 5 | PN – 09- MDF01** | Æ8 | 250-400 | Æ13×35 | ||

| 6 | PN – 12 -MDF01** | Æ12 | 100-250 | Æ13×35 | ||

| 7 | PN – 15-MDF01 | Æ13 | Æ13×38 | |||

| 8 | PN – 15-MDF02 | Æ13 | 10-100 | Æ15×50 | ||

| 9 | PN – 17 -MDF01 | Æ15 | Æ15×50 | |||

| 10 | PN – 05- MDF01 | Æ31 | 1-50 | Æ17×50 | Surface and subsurface cracks, voids in aluminum alloys and austenitic steel etc. | |

| 11 | PN-6 ×8 – TD01 | 6×8 | 900-1700 | Æ31×50 | Surface cracks, voids in ferromagnetic steel. It is used for grooves testing. |

|

| 12 | PN-05- TD 01 | Æ3 | 400-600 | Æ12.5×130 | Surface cracks, voids, corrosion damages in aluminum alloys, ferromagnetic and austenitic steel etc. | |

| 13 | PN-05-TD 02 | Æ3 | 750-1100 | Æ12.5×70 | ||

| 14 | PN-05-TD 04 | Æ4 | 100-450 | Æ15×170 | ||

| 15 | PN-08-TD 01 C | Æ7 | Æ35×150 | Special ECP for the testing of VR2-26 gear pinions of NI-26 helicopters. | ||

| PNR - 03×(5-6)*-TD01 | Æ | Detection of surface defects in aluminum alloys, ferromagnetic and austenitic steel etc. They are intended for the testing of holes of different diameters. They are used a part of the eddy current rotary scanner. |

||||

| 18 | PNR-03×(8.5-9.5)*-TDO1 | Æ3 | 2000-3000 | Æ | ||

| PNR-03×(17-18)*-TD01 | Æ | |||||